Description

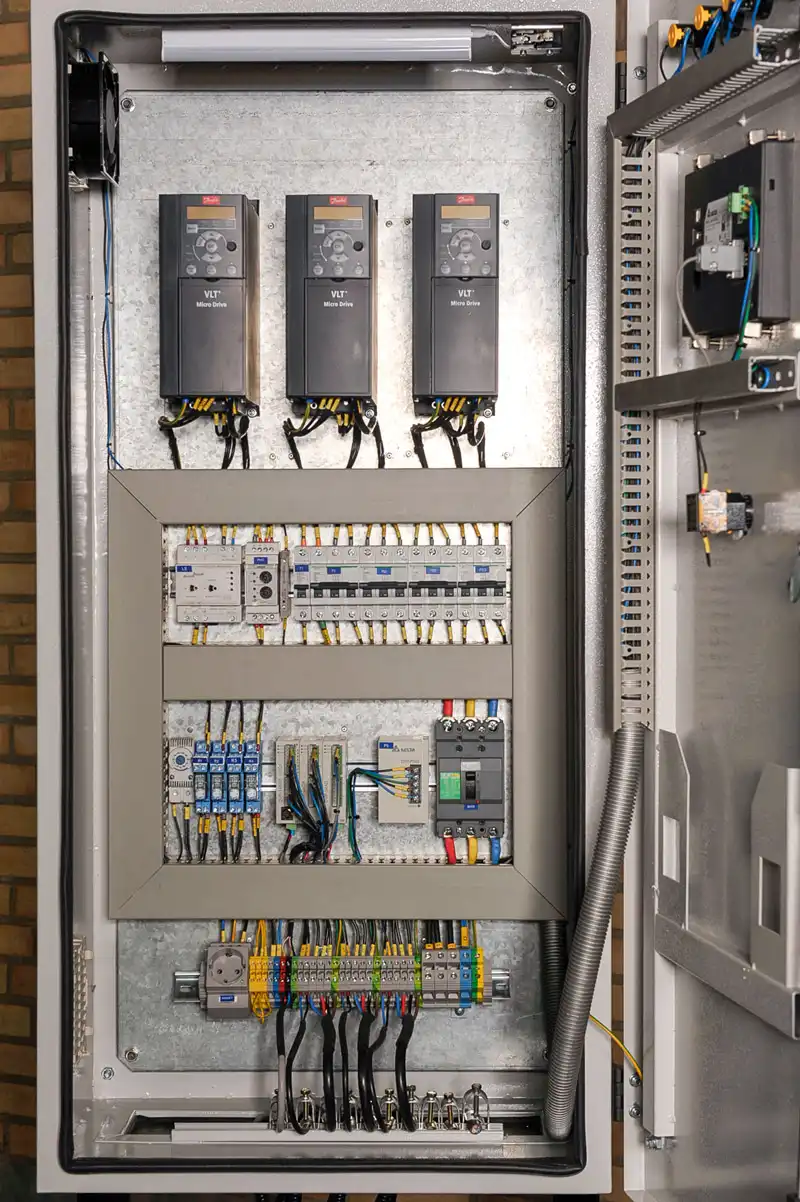

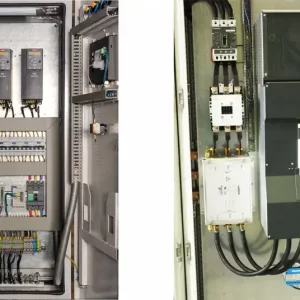

The main parts of the control panel such as the contactor, bimetal, Thermal Circuit Breaker, Miniature Circuit Breaker, Automatic Main Circuit Breaker with Schneider brand, ball bearing fan, terminal and rails, and body with a degree of protection IP54, sheet thickness 1.5 mm with electrostatic paint and including:

- Intelligent command system

- The main rotary switch next to the panel from Schneider / Tavan Rah Sanat brand

- switch/vertical lock, of MITO Brand, Borna /Shiva brand phase control, MITO / OSKAR brand fan valve

- Cable from Zarsim / Khorasan / Hamedan / Rey Afshan brand

- Speed control using Danfoss inverter (variable speed model)

- Panel equipped with PLC from Delta brand with analog input and output in models with variable speed along with monitoring system with HMI 7 INCH (with two years warranty)

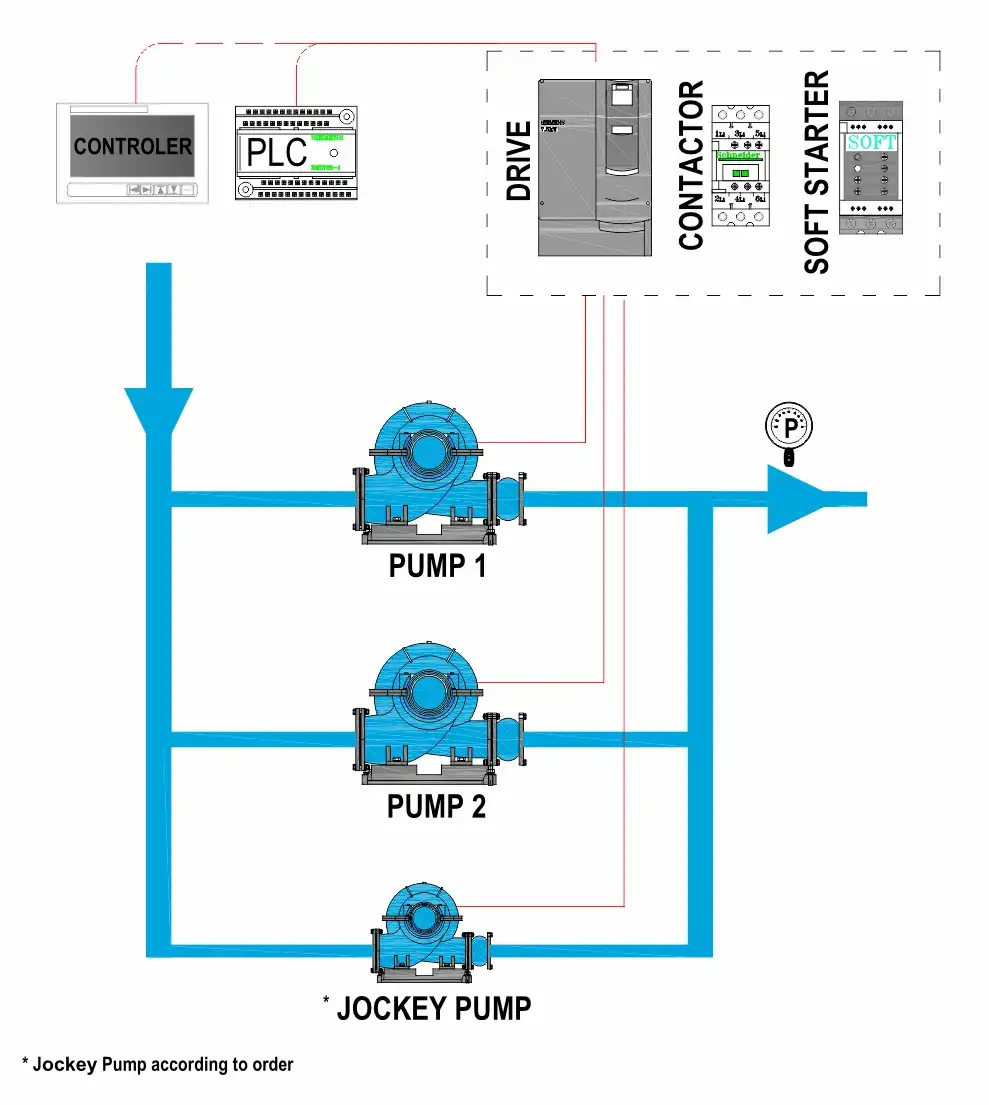

- The gradual increase and decrease of the speed of each electropump according to the amount of consumption

- Removing impact from the system and prolong the life of moving components of the electropump (in the model with variable speed)

- Control with PID and the unique program of Grundfos company (Hyder and MPCF)

- Automatic and manual selection system to test and remove each pump from the circuit in case of technical failure

- Slip control system and starting frequency of pumps to prevent pressure fluctuations

- Self-service system in fire boosters

- Auto Change and Change Over systems (each pump works in equal amount) in on / off and time changing mode

- The signal to turn off the system when there is a lack of water in the circuit and automatic start-up after the water shortage is resolved

- Protection of electropumps against overload by connecting the PTC motor to the PLC and separate control of each alarm

- Protection of electropumps for the number and row of phases

- The use of the contactor and the main switch is 40% greater than the current drawn from the electric motor in the direct start-up.

- Control to stop the turning on and off of electropumps in case of pressure change and control of non-synchronism

- Equal division of the operation between all the main electric pumps so that the operation time is divided between the pumps.

Reviews

There are no reviews yet.